Dyness Knowledge | Recent Advances in Lithium and Sodium Batteries

Power Generation

Dyness Knowledge | Recent Advances in Lithium and Sodium Batteries

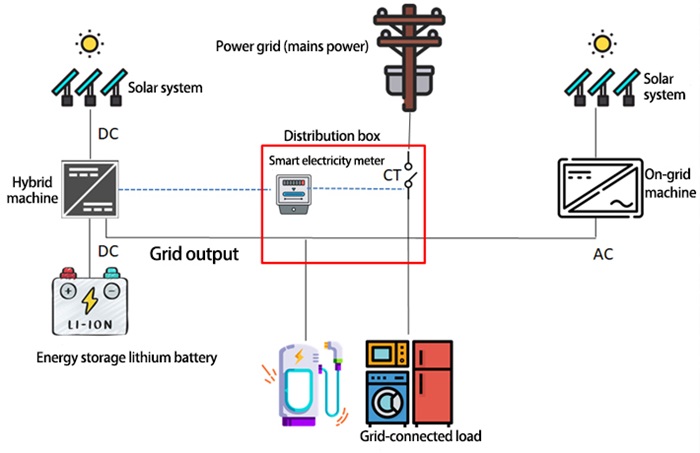

In recent years, with the rapid development of new energy at home and abroad, especially in Europe, balcony photovoltaics have sprung up, and new energy storage batteries have received great attention. This year, the German Institute of Electrical Engineers drafted a document to increase the balcony photovoltaic power limit to 800W, which ushered in another explosion in the European energy storage market. In the process of household users building photovoltaics on a large scale, household energy storage (also known as household energy storage system), which is similar to a micro energy storage power station, is also being vigorously developed to support higher power photovoltaic panels. . The core of household energy storage is the alkali metal battery. This article will give a brief introduction to the alkali metal battery.

1. Background on Alkali Metal Batteries

Due to the high theoretical capacity and low redox potential of metal anodes, alkali metal (lithium Li, sodium Na, and potassium K) battery technologies have attracted extensive attention, especially for the pursuit of high energy density batteries.

Since their commercialization in the early 1990s, rechargeable lithium-ion batteries (LIBs) have dominated the global electrochemical energy storage market over the past two decades, especially in the field of portable products. Li metal is actively considered as the most promising candidate among various alternative anode materials due to its ultrahigh theoretical capacity of 3860 mAh/g and low redox potential of −3.040 V vs. standard hydrogen electrode (SHE) [1] . However, Li-ion intercalation LIBs based on transition metal oxide cathodes and graphite anodes are currently approaching their energy density limit of about 300 Wh/kg, unable to meet the growing demands of high-energy-density battery systems [2].

Practical applications of alkali metal batteries present significant challenges in terms of safety and longevity. First, as the alkali metals continue to deposit/exfoliate non-uniformly, they can penetrate the separator, causing problems such as short circuits, fires, and even explosions when using flammable liquid electrolytes. Second, the high reactivity of alkali metals leads to spontaneous redox reactions with conventional organic electrolytes to form a solid electrolyte interface (SEI) layer. This consumes alkali metal ions and reduces Coulombic efficiency (CE). Some dendrimers may break and detach from the conductive substrate, generating "dead alkali metals", further reducing CE, which has a huge impact on battery cycle life. For example, if the CE is 99% per cycle, after 200 cycles, only a maximum of 13% of capacity is retained [3].

2. Current progress and development of alkali metal batteries

To address the aforementioned challenges in AMBs, researchers have proposed various strategies, including electrolyte formulation [4], separator modification [5], solid electrolyte design [6], artificial SEI construction [7], and anode structure fabrication [8] ]. In this article we mainly discuss related technologies for improving electrolytes.

Wanming Teng et al. believe that for new rechargeable battery technologies, the rational design of advanced electrolytes is a prerequisite for the construction of practical AMBs [3]. Various types of electrolytes have been developed in recent years, including solid electrolytes [9], polymer electrolytes [10], and liquid electrolytes. Carbonate solvents are commonly used in commercial LIBs, but they perform poorly in terms of alkali metal deposition/exfoliation efficiency and dendritic morphology in the anode, resulting in poor cycling stability. Ether solvents (such as 1,2-dimethoxyethane) are relatively compatible with alkali metals. However, its oxidation stability is poor, and the CE value during high-voltage operation is still unsatisfactory and fluctuates greatly.

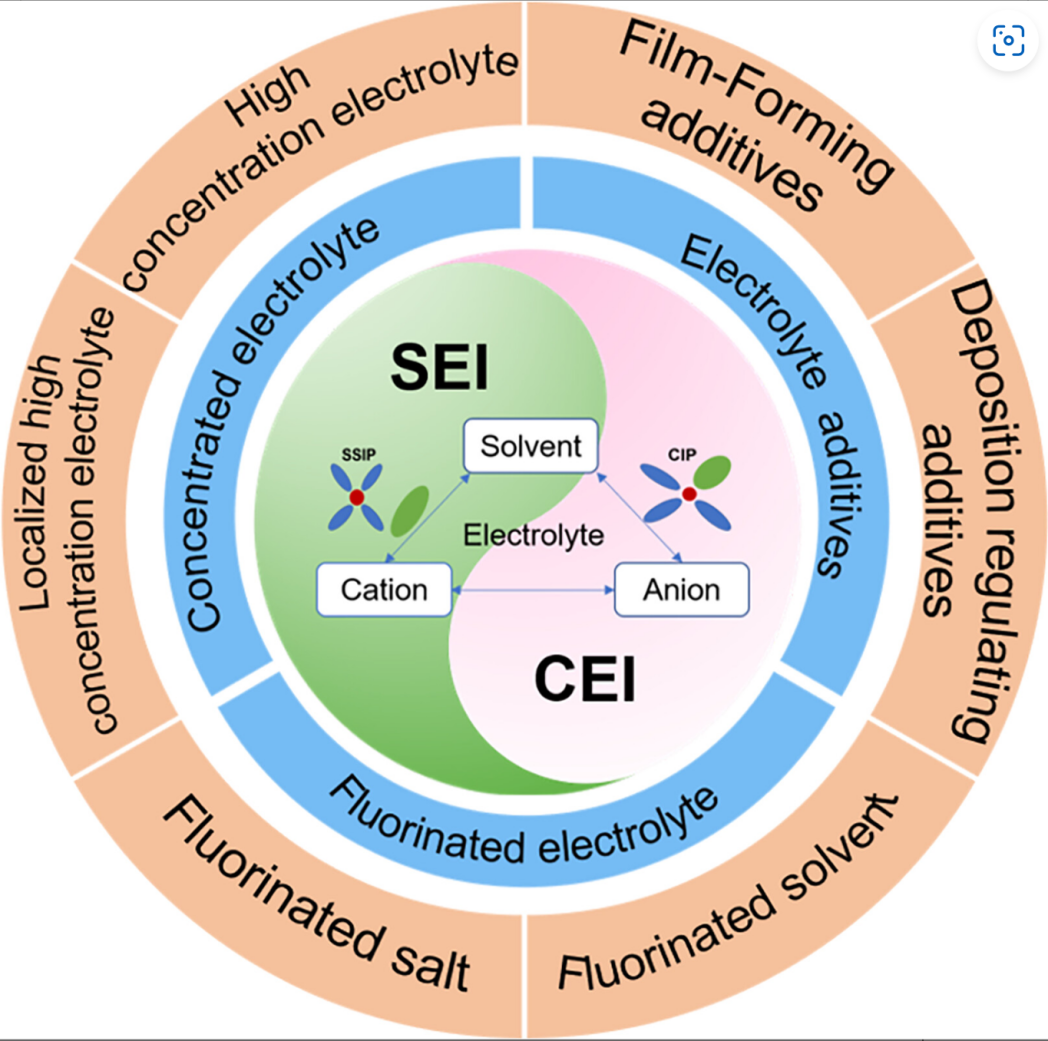

Over the past decade, research on novel electrolytes that stabilize alkali metals has gradually increased. These include: 1) Concentrated electrolytes that reduce the amount of free solvent and mitigate parasitic reactions. 2) Stronger oxidation stability towards fluorinated solvent-based electrolytes due to the high electronegativity of F. 3) Functional additives in novel electrolytes that preferentially react with alkali metals before solvents and alkali metal salts, resulting in a more favorable SEI layer (Fig. 1).

Figure 1 Functional classification of liquid electrolytes[3]

• High concentration of electrolytes

In high-concentration electrolytes (HCEs), solvates mainly exist in the form of contact ion pairs (CIPs) and aggregates in electrolytes (AGGs). This unique dissolved structure with few free solvent molecules improves the oxidative stability of the electrolyte and enhances the reduction stability of the HCE system. At the same time, the interfacial chemistry will be dominated by anions rather than solvents, and anions will be preferentially reduced and decomposed to form SEIs containing more inorganic species. In addition, when the electrolyte concentration exceeds a certain threshold, the electrolyte will have some new physicochemical and electrochemical properties, such as high thermal stability, corrosion inhibition of current collectors, and inhibition of lithium polysulfide dissolution. HCE has thus been extensively studied for its function in stabilizing Li metal anodes and high-voltage cathodes for Li-ion batteries.

• Fluorinated electrolytes

Fluorine (F) is a bipolar element with strong polarity and weak polarity. Fluorine-containing electrolyte components have excellent kinetic reactivity, which can effectively promote the electrochemical performance of AMB. Fluorine-containing electrolyte components can also be used as flame retardants to improve safety. The electron absorption induction effect of F atoms means that fluorinated solvents have higher oxidation resistance and poor reducibility. However, due to the high reduction potential of the fluorinated solvent, it is easier to construct dense LiF-rich interfaces on the anode and cathode surfaces. This prevents the continuous decomposition of the electrolyte and further expands the available electrochemical stability window (ESW).

• Electrolyte additives

In addition to designing advanced solvent-salt systems discussed above, introducing additives into electrolytes has also been considered as a simple and effective way to improve the performance of lithium metal batteries (LMBs). This common approach is also widely used in the lithium-ion battery (LIB) industry. Their role is reflected in: changing the physicochemical properties of the SEI layer, inhibiting the growth of Li dendrites, and promoting the favorable Li+ flux towards the smooth electrodeposition on the Li metal anode. Specifically, for the former type, behaviors such as polymerization, decomposition, or adsorption of additives on the Li metal surface may change the microstructure and/or composition of the interface, thereby affecting Li deposition. For the latter type, additives do not participate in the formation of SEI, but mainly affect the distribution of Li+ flux.

• Advanced electrolyte for Na-Potassium metal batteries

Sodium metal batteries (SMBs) and potassium metal batteries (PMBs) with high energy density have high theoretical specific capacity (Na: 1166 mAh g−1; Potassium: 687 mAh g−1) and low redox due to the metal Na and K anodes. potential (sodium: -2.71 V; potassium: -2.93 V, vs. SHE) has received increasing attention. Since their development is slightly behind LMBs, advanced electrolyte design rules for SMBs and PMBs are usually based on those of LMBs.

3. Summary

Electrolytes, which conduct ionic current between the cathode and anode while sequestering electrons, are considered a key component in enabling new chemical reactions and functions. An ideal electrolyte should possess high safety, high rate performance, thermal stability, electrochemical stability, low cost, especially for hyperreactive alkali metal surfaces, and good electrode/electrolyte interface formation ability.

Despite many advances, the widespread application of electrolytes in AMBs still faces the following challenges:

• Greater understanding of the apparent correlation between the molecular and electronic structures of electrolyte components, their interaction effects with alkali metals, and the synergistic effects between salts, solvents, and additives.

• So far, the understanding of the exact formation mechanism of SEI/CEI is very limited.

• The free movement of Li+ is limited by the strong coordination between Li+ and solvent molecules.

References

[1] X.-B. Cheng, R. Zhang, C.-Z. Zhao, and Q. J. C. r. Zhang, "Toward safe lithium metal anode in rechargeable batteries: a review," vol. 117, no. 15, pp. 10403-10473, 2017.

[2] Z.-D. Huang et al., "Interfacial engineering enables Bi@ C-TiOx microspheres as superpower and long life anode for lithium-ion batteries," vol. 51, pp. 137-145, 2018.

[3] W. Teng et al., "Designing Advanced Liquid Electrolytes for Alkali Metal Batteries: Principles, Progress, and Perspectives," vol. 6, no. 2, p. e12355, 2023.

[4] C. V. Amanchukwu, Z. Yu, X. Kong, J. Qin, Y. Cui, and Z. J. J. o. t. A. C. S. Bao, "A new class of ionically conducting fluorinated ether electrolytes with high electrochemical stability," vol. 142, no. 16, pp. 7393-7403, 2020.

[5] Y. Wang, L. Zhu, J. Wang, Z. Zhang, J. Yu, and Z. J. C. E. J. Yang, "Enhanced chemisorption and catalytic conversion of polysulfides via CoFe@ NC nanocubes modified separator for superior Li–S batteries," vol. 433, p. 133792, 2022.

[6] A. Manthiram, X. Yu, and S. J. N. R. M. Wang, "Lithium battery chemistries enabled by solid-state electrolytes," vol. 2, no. 4, pp. 1-16, 2017.

[7] Y. Liu et al., "An ultrastrong double-layer nanodiamond interface for stable lithium metal anodes," vol. 2, no. 8, pp. 1595-1609, 2018.

[8] M. Ye, X. Jin, X. Nan, J. Gao, and L. J. E. S. M. Qu, "Paraffin wax protecting 3D non-dendritic lithium for backside-plated lithium metal anode," vol. 24, pp. 153-159, 2020.

[9] X.-B. Cheng, C.-Z. Zhao, Y.-X. Yao, H. Liu, and Q. J. C. Zhang, "Recent advances in energy chemistry between solid-state electrolyte and safe lithium-metal anodes," vol. 5, no. 1, pp. 74-96, 2019.

[10] S.-M. Hao et al., "Lithium-conducting branched polymers: New paradigm of solid-state electrolytes for batteries," vol. 21, no. 18, pp. 7435-7447, 2021.

Writer |Dr.Zhou Jian(BEng,Mphil,PhD)

Text audit |Chris Ma

Dyness Digital Energy Technology Co., LTD

WhatsApp: +86 181 3643 0896 Email: info@dyness-tech.com

Address: No.688, Liupu Road, Suzhou, Jiangsu China

Dyness community: https://www.facebook.com/groups/735600200902322

.png?width=350&height=70&name=HOME%20OF%20CLEAN%20ENERGY%20trans%20(350%20%C3%97%2070%20px).png)