Dyness Knowledge | Solar and energy storage must-learn terminology(C&I)

Power Generation

Dyness Knowledge | Solar and energy storage must-learn terminology(C&I)

Industrial and commercial energy storage is becoming a key field to promote the development of new energy. By rationally selecting batteries with high energy density, low self-discharge rate, and good consistency, efficient storage and utilization of electric energy can be realized, and the stable supply and utilization of clean energy can be promoted.

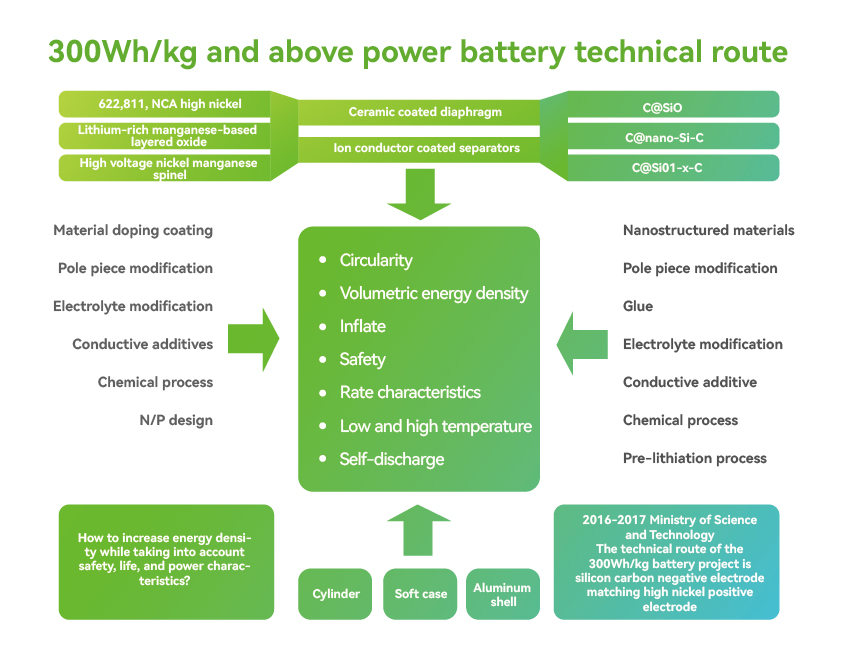

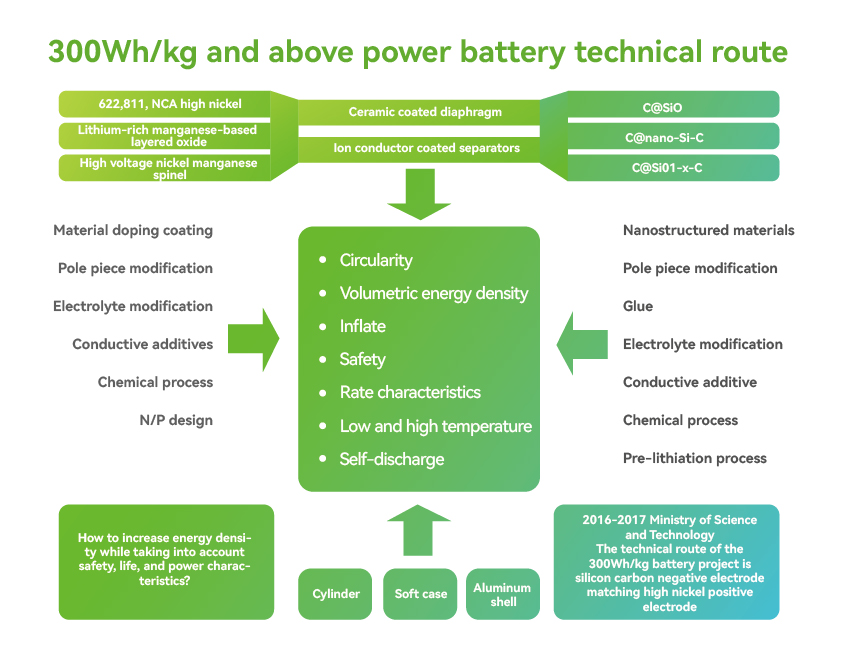

Energy density Conception

Energy density refers to the amount of energy stored in a certain unit of space or mass of matter. The energy density of a battery is the electrical energy released by the average unit volume or mass of the battery, generally divided into two dimensions: gravimetric energy density and volumetric energy density. The greater the energy density of the battery, the more electricity can be stored per unit volume or weight.

There are two different concepts of battery energy density, one is the energy density of a single cell, and the other is the energy density of a battery system.

The energy density of the system refers to the weight or volume of the entire battery system after the monomer combination is completed. The battery system includes a battery management system, thermal management system, high and low-voltage circuits, etc.

Measures to improve system energy density:

1. Increase battery energy density

2. Improve the grouping efficiency of battery packs

Optimized layout structure: In terms of external dimensions, the internal layout of the system can be optimized to make the internal components of the battery pack more compact and efficient.

Topology optimization: Through simulation calculation, the weight reduction design can be realized under the premise of ensuring rigidity and structural reliability. Through this technology, topology optimization and shape optimization can be realized to finally help realize the light weight of the battery box.

Material selection: choose low-density materials, such as the battery pack cover has gradually changed from the traditional sheet metal cover to the composite material cover, which can reduce the weight by about 35%. For the lower box of the battery pack, it has gradually changed from the traditional sheet metal solution to the aluminum profile solution, reducing the weight by about 40%, and the weight reduction effect is obvious.

3. Optimize system design: optimize the layout of each component of the battery system and the heat dissipation system.

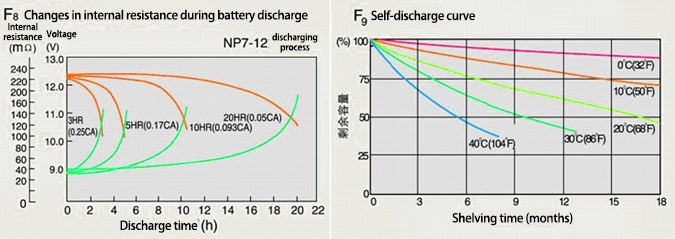

Self-discharge rate Conception

The self-discharge rate of the battery refers to the natural discharge rate generated by the internal chemical reaction of the battery when it is not in use, also known as the charge retention capacity. Due to the inevitable internal reaction of the battery, even if there is no external load, the battery will discharge naturally, which is mainly affected by factors such as the battery manufacturing process, materials, and storage conditions.

The raw materials for making batteries cannot be 100% pure, there will always be impurities mixed in the middle, and there will inevitably be self-discharge.

Influencing factors

1. Temperature: the higher the temperature, the faster the self-discharge rate

2. Electrolyte: Different types of electrolytes also have different effects on the self-discharge rate

3. Metal materials: Different metal materials have different effects on the self-discharge rate

4. Storage conditions: Storage conditions also have different effects on the self-discharge rate

Harm:

1. Self-discharge is accompanied by an increase in battery internal resistance, resulting in a decrease in battery load capacity

2. Over-discharge may lead to loss of capacity that cannot be reversibly compensated.

3. The self-discharge of the metal impurity type causes the aperture of the diaphragm to be blocked and even pierces the diaphragm to cause a local short circuit, endangering the safety of the battery

4. Self-discharge leads to an increase in the SOC difference between batteries, and the capacity of the battery pack decreases

5. Large differences in SOC can easily lead to overcharge and over-discharge of the battery

How to reduce the self-discharge rate

1. Lower the temperature: storing the battery at a lower temperature can effectively alleviate the self-discharge rate.

2. Reduce the area of metal materials: Reducing the area of metal materials can reduce the self-discharge rate.

3. Correct storage: Correct storage can effectively prolong battery life and reduce the self-discharge rate. The battery should be stored in a dry, cool, and well-ventilated place, and avoid long-term non-use.

Cell consistency Conception

The consistency of lithium batteries refers to the consistency of the initial performance indicators of the single batteries used in groups, including capacity, impedance, electrical characteristics of electrodes, electrical connections, temperature characteristics, decay speed, etc. The inconsistency of the above factors will directly affect the difference in output electrical parameters during operation.

Inconsistency hazard

1. Capacity loss. Lithium battery packs are composed of single cells. The capacity conforms to the principle of wooden barrels. The capacity of the worst cell determines the capacity of the entire battery pack.

2. Loss of lifespan. Small-capacity batteries are fully charged and discharged every time. If the output is too strong, it is likely to be the first to reach the point of lifespan. When the life of a battery cell ends, a group of battery cells welded together will also come to an end of life.

3. The internal resistance increases. With different internal resistances, the same current flows, and the cells with large internal resistances generate relatively more heat. If the temperature of the battery is too high, the deterioration speed will be accelerated, and the internal resistance will further increase. Internal resistance and temperature rise form a pair of negative feedback, which accelerates the deterioration of high internal resistance cells.

Inconsistent control

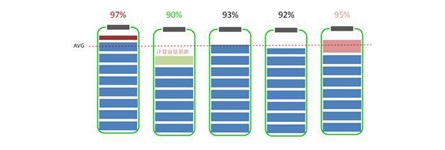

1. Sorting, batteries of different batches should not be used together theoretically. Even the cells of the same batch need to be screened, and the cells with relatively concentrated parameters are placed in a lithium battery pack, in the same battery pack.

2. Thermal management: For batteries with inconsistent internal resistance, the heat generated is not the same. The addition of the thermal management system can adjust the temperature difference of the entire lithium battery pack to keep it in a small range. The battery cells that generate more heat still have a high-temperature rise, but they will not widen the gap with other batteries, and there will be no obvious difference in the level of degradation.

3. Battery balance management, battery management system BMS design balance function. Ensure a good use environment for the lithium battery pack, try to ensure a constant temperature, reduce vibration, and ensure that water, dust, etc. pollute the battery pole. Grasp the development law of inconsistency of single cells in lithium battery packs, and adjust or replace batteries with extreme parameters in time to ensure that the inconsistency of battery pack parameters does not increase with use time.

Dyness has been deeply involved in the field of energy storage for many years, has rich experience in battery research and development and Pack design, and has mature industrial design and system research and development precipitation. Through the mature cell sorting system and BMS self-developed technology, the cell consistency and battery self-discharge rate are strictly controlled. Fully guarantee the high energy density and high safety of the battery system of its own energy storage products.

Dyness Digital Energy Technology Co., LTD

WhatsApp: +86 181 3643 0896 Email: info@dyness-tech.com

Address: No.688, Liupu Road, Suzhou, Jiangsu China

Dyness community: https://www.facebook.com/groups/735600200902322