Dyness Knowledge | Introduction of DC coupling system for home energy storage

Power Generation

Dyness Knowledge | Introduction of DC coupling system for home energy storage

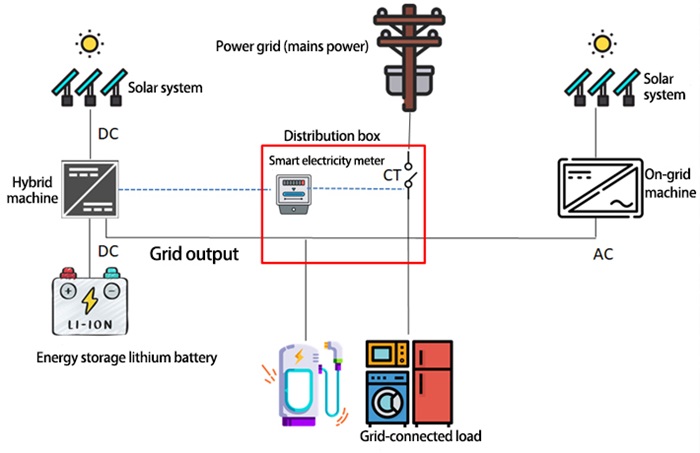

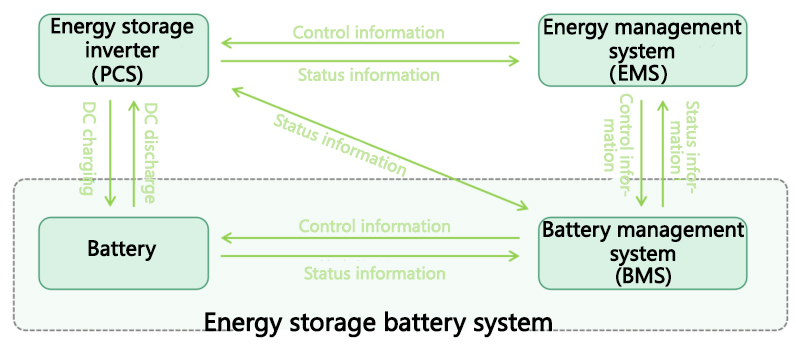

The so-called DC coupling is judged according to the battery’s external charging power source. It is DC coupling to charge the battery through DC power conversion, and AC coupling to convert AC power to DC power. In the photovoltaic storage system, the photovoltaic module converts light energy into electrical energy through the built-in MPP tracking module and the hybrid inverter's DC/DC conversion module. And through the components such as inductors and capacitors inside the inverter to achieve boost rectification and then charge the battery. Overall such a conversion process is called DC coupling. An energy storage system that realizes battery charging through DC coupling is called a DC coupling system.

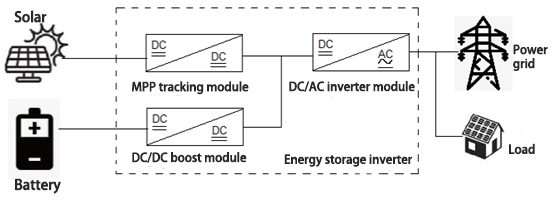

The DC coupling system is suitable for end customers with new energy storage needs due to its high level of functional integration and fewer times of power conversions. There is no need to install both photovoltaic inverters and energy storage inverters, and directly use the form of energy storage inverters + batteries + modules. Among them, there are two common system structures. One is to build the battery DC/DC boost module into the inverter, such as a hybrid inverter (Figure 1). In this kind of system, the design of the inverter is relatively complicated, but the compatibility with the battery is stronger, and the application scenarios are wider.

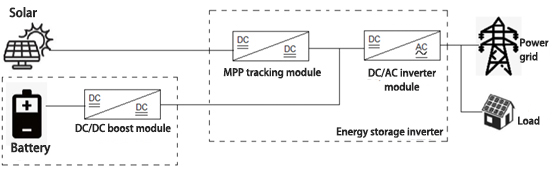

Another system is the battery with its own boost function module (Figure 2). In such a system, the design requirements for the inverter are relatively low. Batteries can be made more standardized, and the selection is relatively wider. Compared with the system in Figure 1, the maintenance cost of the inverter in the system in Figure 2 is lower, but the overall design requirements for the battery pack have been improved, and the compatibility of the inverter with the battery is poor. Two separate products may have out-of-sync communications or even be incompatible. Therefore, some manufacturers will sell them in the form of an "inverter + battery" package.

In recent years, a new system scheme has appeared in the DC coupling system and has been widely used gradually. The separate design of the MPP tracking module and inverter is presented by the product of photovoltaic optimizer + energy storage inverter. Compared with conventional components directly connected to the energy storage inverter, the photovoltaic optimizer performs the MPP tracking of each component for the energy storage inverter at the front end. Reduce system output power reduction caused by partial shading of photovoltaic modules, or damage and other factors. In this way, the photovoltaic system as a whole maintains an output in a high-power state.

Dyness Digital Energy Technology Co., LTD

Tel: +86 400 666 0655 Email: info@dyness-tech.com

Address: No.688, Liupu Road, Suzhou, Jiangsu China

Dyness community: https://www.facebook.com/groups/735600200902322