LONGi-Solar & Storage Finance Virtual Summit: Reliable, High-Performance Modules Help Solve Utility Solar Plant Underperformance Issues

Why are some utility solar plants underperforming? How much of that underperformance is the result of overforecasted production estimates and models or actual yield issues related to faulty equipment or other factors? How do developers and financiers balance innovation and bankability? When it comes to large-format modules, how big is too big?

These were some of the questions posed during a lively panel discussion session titled “Improving Yield: Ensuring A Bankable ‘March of Progress’” at the recent Solar & Storage Finance USA virtual summit, produced by Solar Media. I was joined by my fellow panelists from Estuary Capital, Wells Fargo REEF, Lightsource BP and DNV.

Why Are Some Utility Solar Plants Underperforming?

Jon Previtali of Wells Fargo talked about the issue of what he called the “endemic underperformance” of some utility solar plants, mainly because of unintentional biases introduced into modeled production estimates. He explained how his company has instituted an in-house “parallel production estimate” to compare with P50 and P95/99 models, which provides a more predictable estimate of a portfolio’s performance—and less risk for project investors and owners.

Noting that “plenty of assets are performing fine,” DNV’s Anat Razoin explained how the IE firm’s data-driven energy assessment validation tools have found different reasons for production gaps in solar plants. Whether it’s weather, operational or other issues causing the underperformance, she stressed the importance of taking a “holistic view” in evaluating the problems.

Balancing Innovation and Bankability

On the topic of balancing innovation and bankability, Sara Kayal of Lightsource BP stressed the importance of having a “feedback loop” to assess why assets might be underperforming and to make adjustments. This includes fostering a close relationship with module manufacturers and other suppliers, getting beyond what she called “a black box approach,” being more transparent about what’s going on in the supplier’s R&D pipeline and sharing test data.

There have been many PV cell and module innovations in recent years that continue to drive down balance of system (BOS) costs and the levelized cost of energy (LCOE) of solar plants, but also improve reliability, I explained. The advent of monocrystalline PERC cells, multibusbar designs, improved cell density, double-glass bifacial modules and other new technologies have led to better performance and reliability. In addition, the wider use of accelerated testing and factory audits conducted by independent labs such as PVEL and RETC as well as comprehensive in-house R&D, testing and production quality systems at LONGi Solar and other companies show how far the industry has come in creating consistently bankable products.

Large-Format Modules: How Big Is Too Big?

Large-format modules continue to be a hot topic of discussion, and that trend continued during the panel. While the benefits of the larger modules are apparent—significant BOS cost savings, better LCOE—there are also some concerns. For example, one questioner asked, when it comes to large-format modules, how big is too big?

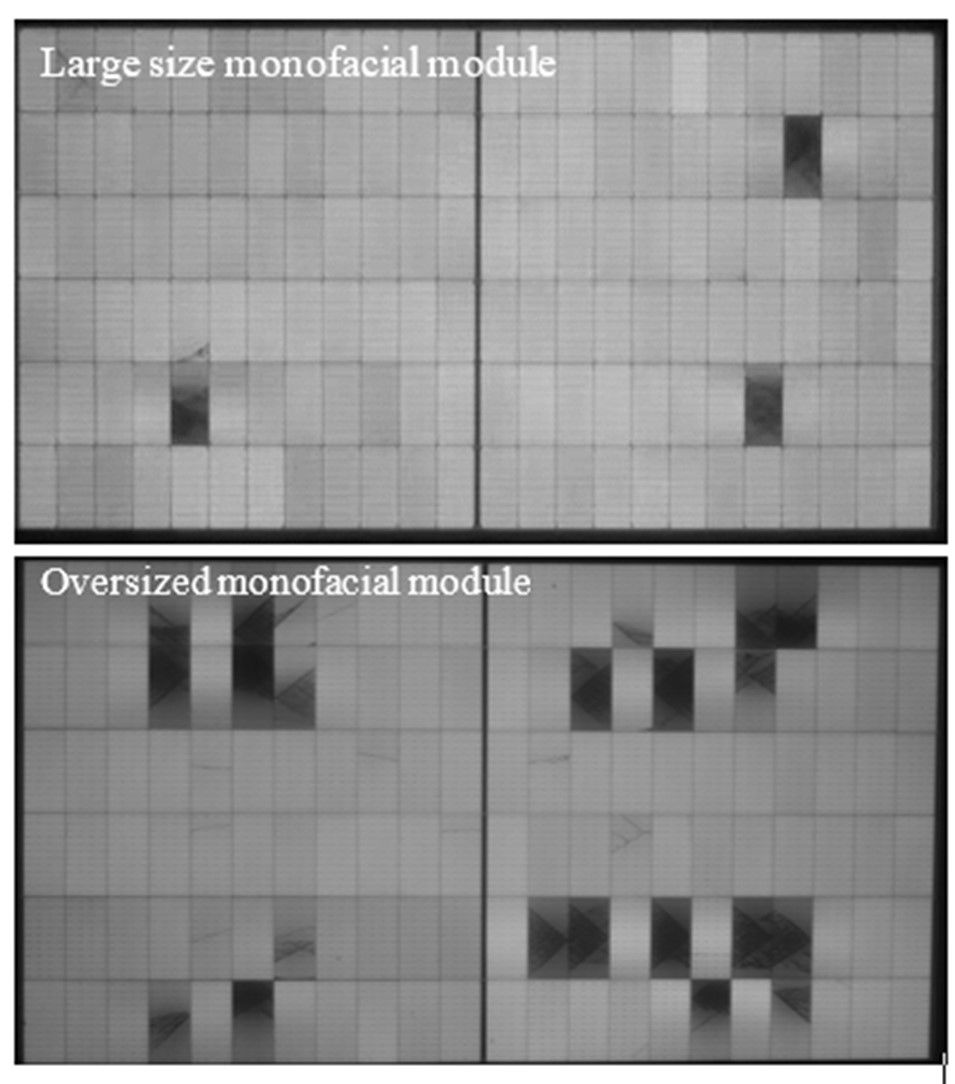

I laid out a variety of reasons why the oversized, 210-mm-wafer-based modules already raise some reliability concerns. Given their added surface area and significantly longer span along module width in comparison to the large-size, 182-mm-wafer-based modules made by LONGi and other companies, tests have shown that the oversized modules experience considerably more stress-related deformation and are more prone to microcracking and long-term degradation. There are also concerns about their durability during extreme weather events and lifetime performance when subjected to many such events.

Focus on Efficiency is Key

I made the point that we cannot make modules any bigger without compromising on reliability, but to put our focus instead on cell and module efficiency improvements to continue lowering BOS costs and improving LCOE. For example, we are developing high-efficiency N-type cell technologies that will offer better light-induced degradation (LID) and temperature coefficient performance than PERC cells as well as improved bifaciality. Although this technology is still more expensive than today’s standard PERC architectures, it will soon be in volume production and become cost competitive at LCOE level for certain projects and locations.

One key takeaway from the panel discussion is that while utility solar plant underperformance needs to be addressed, there are solutions. Module reliability and performance throughout the lifetime of PV projects is one of the most important ways that asset owners can ensure consistent energy yield and return on investment for all PV projects.